Rotating beam fatigue testing systems were first developed in the mid 1800s by a german railroad engineer named august wöhler.

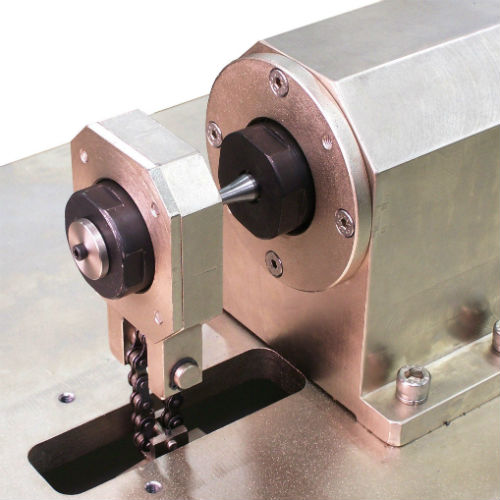

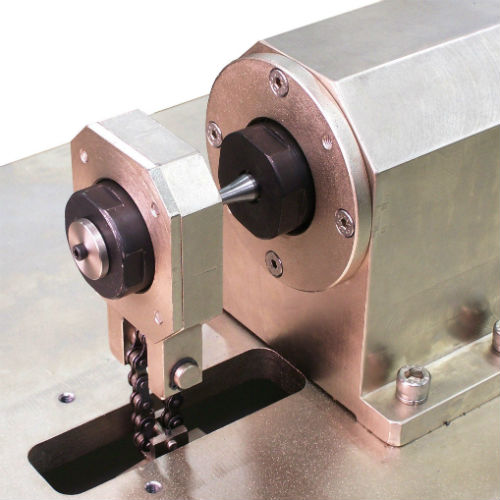

Rotating beam fatigue testing machine.

He designed the machine to test railroad car axles and investigate axle brake failures.

Fatigue dynamics offers a full service line of fatigue testing machines which include rotating beam fracture testing plate bending and crack initiation testing equipment.

This paper presents the desi gn and fabrication of a new m echanical fatigue testing machine based on rotating beams with the o bjective of test ing high cycle fatigue and service life loads.

Rotary bending fatigue testing.

Based on wohler s design it uses a motor to rotate a circular cantilever specimen with a load at its free end.

Additionally we can machine test samples and perform testing onsite per customer specifications with reporting.

The advanced materials research laboratory amrl is home to three r r.

The purpose is to carry out rotating bar bending fatigue tests without deliberately introducing stress concentration in accordance with din 50113.

The machine design is based on the rotating beam principle.

Rotating fatigue machine this machine demonstrates the fatigue failure of materials when subject to alternating stresses.

A test piece mounted as a cantilever with single point loading is made to rotate and thus subjected to a bending moment.

The principles upon which that machine was developed still apply today.