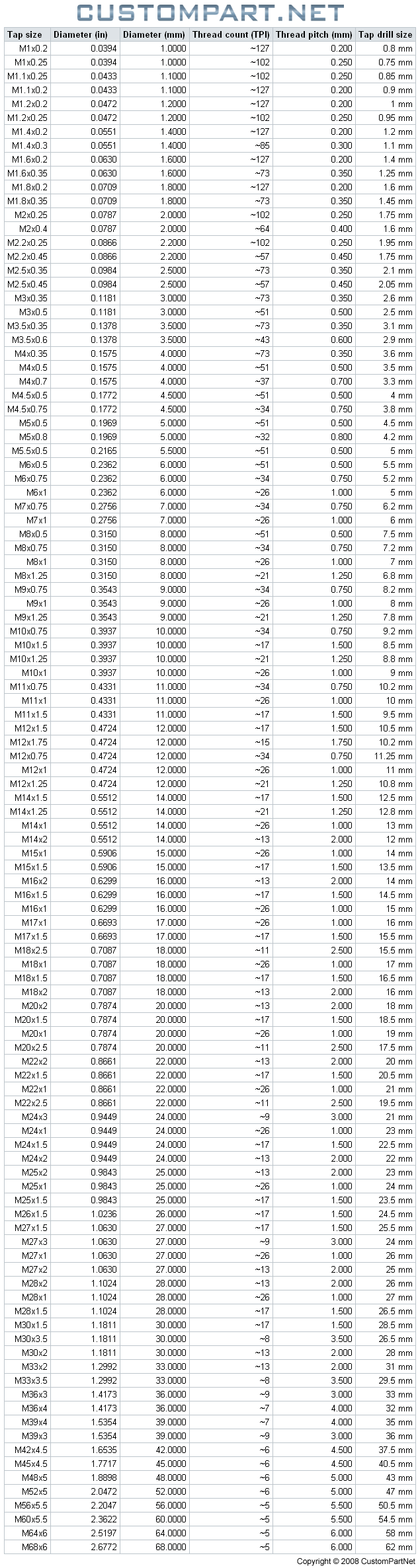

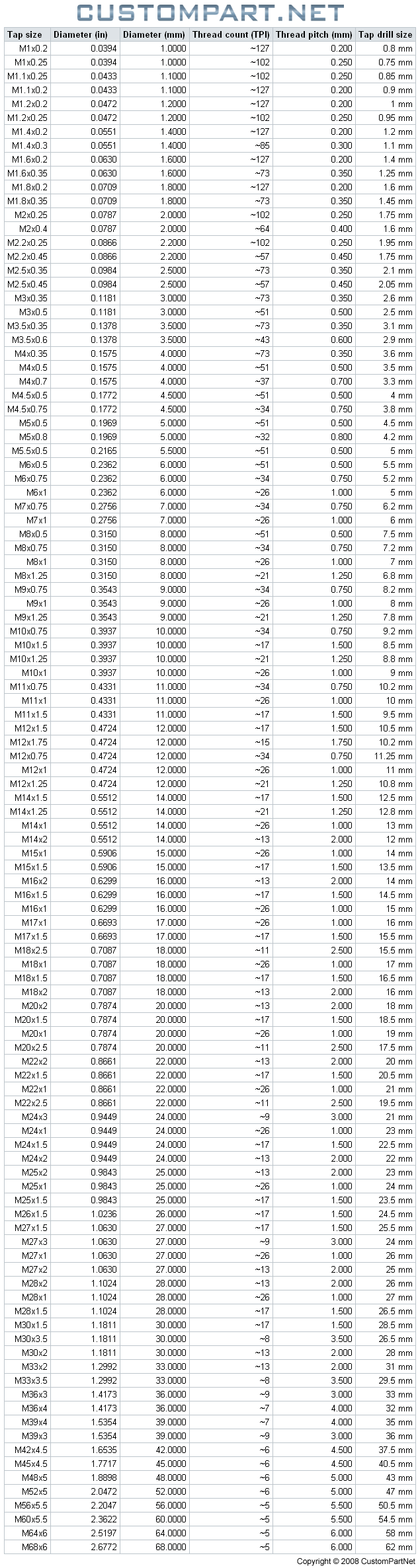

Calculations are done according to roll form tap drill charts which are given in the machinery s handbook.

Roll form tap drill size calculator.

Desired thread size and of full thread are input parameters for the calculator.

The length of the thread to be produced is not limited by chips.

In mm closest standard drill.

The druck s style of roll form tap is designed to work in a wide range of materials and is not material specific.

To establish tap drill sizes for metric size roll forming taps tap drill size basic tap o d.

Mm of thread desired x mm pitch 147 06 example m8 x 1 25 tap with 65 thread 8 65 x 1 25 7 45 mm dia.

Tap drill size calculator.

This website uses cookies we use cookies to make our site work.

Depending on the workpiece material the essential advantages of the cold forming of threads are not only excellent surface quality but also higher static and dynamic strength of the thread.

Form taps various styles.

By using this calculator you agree to the terms and conditions.

The tap drill size of a hole that will be cold form tapped is usually bigger than it cutting tap counterpart.

Calculates drill sizes for cutting and thread roll forming taps.

Tap drill size calculator to minimize tapping problems and lengthen tool life use the largest drill possible to produce a minor diameter that will result in the lowest percentage of full thread consistent with adequate strength.

77 thread is what you want to use a 100 thread is 3 4 qtr or 6 8 th of the full 60 triangle which is the maximum allowed height of a full thread the v shape including flats.